The manufacture of corrugated packaging is generally classified into two phases:

A) Containerboard making combining and cutting.

B) Box manufacturing & designing.

Corrugated Cartons

A) Containerboard making combining and cutting.

1- The Main Stream is being fed with the main raw material (Paper roll):

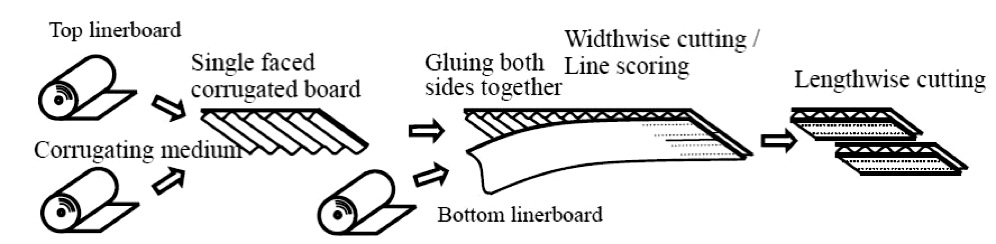

3 Paper rolls to produce a single corrugated board.

5 Paper rolls to produce a double corrugated board.

2- The paper is steam-heated and pressed to form corrugated cardboard.

3- One roll of cardboard is corrugated; which is called the corrugating medium, as it is placed in the middle between two flat sheets, a corrugating medium is pressed into a wave-like shape (flutes).

4- Corrugated layer sandwiching; the corrugated board is glued to both a top

sheet and a bottom sheet of linerboard. Corn starch glue bonds

the corrugated medium (wavy layer) to the liners (layers of paper).

5- The cardboard is then passed over steam-heated plates, which cure the glue.

Note: Two liners and a corrugated medium make up the standard three-layer corrugated board and three liners and two corrugated mediums make up the standard five-layer corrugated board.